PVC patches have become increasingly popular in fashion, branding, and outdoor gear. They are flexible, durable, and highly customizable. But are they the right choice for your project? In this guide, we’ll explore everything about PVC patches, including their benefits, drawbacks, common uses, and tips for choosing the best patches for your needs.

What Are PVC Patches?

PVC patches, also called polyvinyl chloride patches, are made from soft, rubber-like plastic. Unlike embroidered or woven patches, they are waterproof, resistant to fading, and maintain their shape over time. Custom PVC patches can be created in almost any shape or color, including 2D PVC patches with flat designs or 3D PVC patches with raised details.

Key features of PVC patches include:

Durable against water, sun, and extreme temperatures

Flexible and resistant to tearing

Easy to clean with a damp cloth

Ideal for uniforms, hats, jackets, backpacks, and outdoor gear

Advantages of PVC Patches

PVC patches are popular because they combine durability, customization, and aesthetic appeal. Let’s break down the key benefits in detail:

1. Exceptional Durability

PVC patches can withstand harsh conditions like rain, sun, snow, or heavy wear. They don’t fray, peel, or crack like embroidered or woven patches. This makes them ideal for:

Military and tactical gear

Outdoor jackets and backpacks

Sports team uniforms

Equipment like tents, boat covers, and gear bags

2. Weather and Water Resistance

PVC material is naturally waterproof and UV-resistant. Even prolonged exposure to sunlight or water won’t fade the colors or damage the shape. This ensures your patches remain vibrant and intact in all environments.

3. High Customization Options

PVC patches can be molded into any shape or size. You can create:

2D PVC patches: Flat with defined outlines for logos or icons

3D PVC patches: Layered, sculpted, and tactile designs for maximum impact

Multi-colored designs using Pantone matching for brand consistency

4. Easy Maintenance

Cleaning PVC patches is simple. A damp cloth or mild soap solution restores their original look. There’s no need for special care like with embroidered patches.

5. Low Cost in Bulk

PVC patches are often more affordable than embroidered patches, especially for large orders. They provide professional quality at a lower cost per unit, which is great for organizations or businesses needing multiple patches.

6. Long-Lasting Aesthetic Appeal

The rubber-like material allows intricate details, crisp lines, and bold colors. Even after repeated use, the patch keeps its 3D effect, making your logos and designs stand out.

| Advantage | Explanation |

| Durability | Resistant to tear, fray, or peeling |

| Water & UV Resistance | Withstands outdoor conditions without fading |

| Customization | 2D or 3D designs, any shape or Pantone color |

| Easy Maintenance | Wipe clean, no special care needed |

| Cost-Effective | Affordable, especially for bulk orders |

| Professional Appearance | Crisp, defined designs for logos, morale, or branding |

Disadvantages of PVC Patches

Despite the many benefits, PVC patches also have some limitations. Being aware of these helps you choose the right patch for your needs.

1. Stiffness

PVC patches can feel rigid, especially in cold temperatures. This might be uncomfortable on items worn close to the skin, like sleeves or collars.

2. Environmental Impact

PVC is a type of plastic. Its production and disposal can have environmental consequences. Choosing high-quality manufacturers who implement sustainable practices can reduce the impact.

3. Detail Limitations

While PVC allows detailed designs, extremely fine patterns may not be as sharp as embroidery. Small text or thin lines can be harder to achieve in PVC patches.

4. Curling or Warping

Thin PVC patches or certain designs may curl at the edges under high heat or prolonged sunlight. Proper backing, like Velcro or strong adhesive, helps reduce this risk.

5. Application Restrictions

Iron-on or adhesive backings can fail if applied incorrectly. Sewing PVC patches is more durable but requires additional effort.

6. Temperature Sensitivity

Although durable, PVC can become harder and less flexible in extremely cold weather, which may affect comfort and attachment reliability.

| Disadvantage | Explanation |

| Stiffness | Less flexible in cold temperatures |

| Environmental Concerns | PVC production and disposal impact the environment |

| Detail Limitations | Extremely fine designs may not be sharp |

| Curling Risk | Edges may curl under heat or sunlight |

| Application Challenges | Iron-on or adhesive may fail without proper technique |

| Temperature Sensitivity | Hardens in extreme cold, may affect comfort |

Types of PVC Patches

PVC patches can be divided into 2D PVC patches and 3D PVC patches:

2D PVC Patches: Flat designs with raised areas for details. Common for logos and simple patterns.

3D PVC Patches: Sculpted, layered designs with depth. Ideal for complex logos and eye-catching emblems.

Choosing between 2D and 3D depends on your style and application. 3D PVC patches are visually striking but may cost slightly more.

Applications of PVC Patches

PVC patches are used in many areas:

Military & Tactical Gear: Morale patches on uniforms; Velcro backing for easy swapping

Outdoor Equipment: Boat covers, tents, backpacks withstand harsh weather

Fashion & Apparel: Hats, jackets, and bags get a polished, professional look

Promotional Items: Brands use custom PVC patches for giveaways, badges, and events

Footwear Accessories: Shoe charms, crocs, or sneakers personalized with PVC patches

Quick Application Methods:

Sew-on: Most durable and reliable

Iron-on: Convenient but needs correct temperature

Velcro: Flexible for removable patches

Adhesive: Good for smooth surfaces; less durable

Creating custom PVC patches is a meticulous process that combines artistry and precision to produce durable and visually striking patches. Here’s a detailed look at each step involved:

1. Design

The first step in creating custom PVC patches is to finalize the design. This involves choosing the colors, shapes, and textures that will bring your vision to life. You can opt for a flat 2D design or add depth with 3D effects. The design phase is crucial because it sets the foundation for the entire production process. High-resolution artwork is essential to ensure that the details are captured accurately.

2. Mold Creation

Once the design is finalized, a custom mold is created specifically for your patch. The mold is a negative impression of your design, which will be used to shape the PVC material. This step requires precision to ensure that every detail of the design is accurately represented in the mold. The mold is typically made from a durable material like metal or high-quality plastic to withstand the production process.

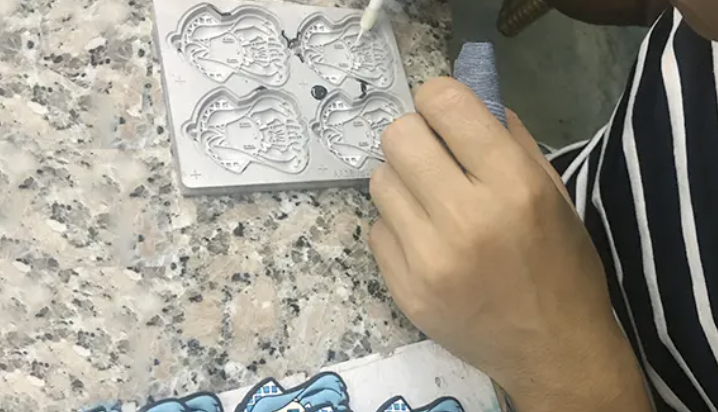

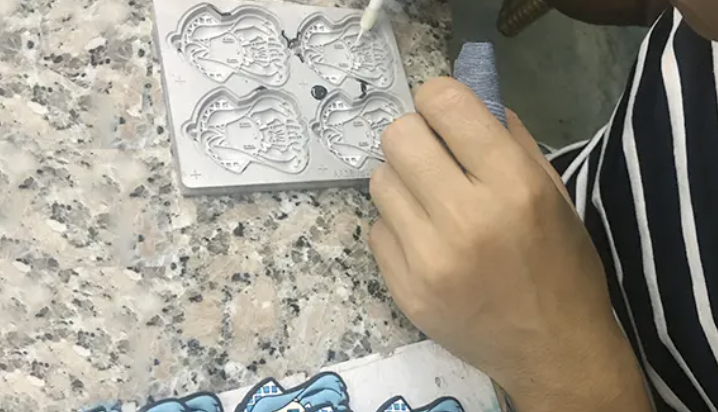

3. Layering

With the mold ready, the next step is to pour colored PVC material into the mold. This is done layer by layer, with each layer carefully placed to build up the design. The layering process allows for intricate details and multiple colors to be incorporated into the patch. Each layer is carefully poured and spread to ensure even coverage and precise alignment with the design.

4. Heat Treatment

After the layers are in place, the patch undergoes a heat treatment process. This step is crucial as it cures the PVC, ensuring that the layers bond together securely and the patch maintains its shape. The heat treatment also helps to set the colors, making them vibrant and long-lasting. The patch is typically placed in an oven or a specialized heat press for this process, with temperatures and durations carefully controlled to achieve the desired results.

5. Trimming & Backing

Once the patch has been heat-treated and the layers have fully bonded, any excess material is carefully trimmed away. This step ensures that the edges of the patch are clean and smooth. After trimming, the patch is backed with a durable material to provide stability and make it easy to attach. Options for backing include sew-on, Velcro, or adhesive backing, depending on the intended use of the patch.

Final Quality Check

Before the patch is ready for use, it undergoes a final quality check. This involves inspecting the patch for any imperfections, ensuring that the colors are vibrant, and verifying that the layers are securely bonded. Any patches that do not meet the high standards are discarded, ensuring that only the best quality patches are delivered to customers.

FAQs About PVC Patches

How long do PVC patches last?

They last for years even in harsh weather. Quality and attachment method influence longevity.

Can I order PVC patches in small quantities?

Yes. Many manufacturers, like QingHan, allow small or bulk orders.

Are PVC patches eco-friendly?

PVC is plastic. Production and disposal impact the environment, but durability reduces frequent replacements.

Can I iron on PVC patches?

Yes, if the patch has an iron-on backing. Follow manufacturer instructions to prevent damage.

What’s the difference between PVC and silicone patches?

PVC is slightly stiffer and more affordable. Silicone is softer and better for flexible items.

Conclusion

PVC patches are versatile, durable, and customizable. They offer bold colors, unique designs, and resistance to wear, water, and sunlight. While they have some drawbacks, such as stiffness and environmental concerns, their benefits often outweigh the cons.

Whether for fashion, military gear, or promotional purposes, custom PVC patches provide a practical and visually appealing solution. They are ideal for clothing, bags, hats, outdoor equipment, and more. For premium quality PVC patches, trusted manufacturers like Huisui International Industrial Ltd.offer professional design support, fast production, and multiple backing options to meet your specific needs.